Power Up From All Sources Off

Cell Power Up Notation

The following procedure covers the power up of the 2V08 Sideskin Roof Outer Cell when the cell has been completely powered down. This procedure provides full power up instruction for the cell and readies the cell for automatic mode of operation. The nature of the cell's "Power Up Procedure" will be conditioned by the manner in which the previous cycling was terminated. In actual operation, some steps may only need to be verified.

Make sure the Pre-Start Check procedure has been performed!

Remove and clear any lockouts throughout the 2V08 Sideskin Roof Outer Cell. Follow procedures outlined in the Lockout / Tagout (LOTO) Placards posted on the Power Distribution Panel.

Follow all plant guidelines and regulations for start-up safety. Follow all safety warning labels posted on the equipment. Refer to the Lockout / Tagout (LOTO) placard for energy source locations. Failure to comply could result in severe personal injury or death, and/or equipment damage.

Allow only personnel with appropriate training and experience to operate or service the equipment. The use of untrained or inexperienced personnel to operate or service the equipment can result in injury, including death, to themselves and others, and/or damage to the equipment.

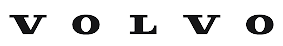

Step 1: ABB Tip Dresser

- At each ABB Tip Dresser, place the rotary disconnect to the "ON" position.

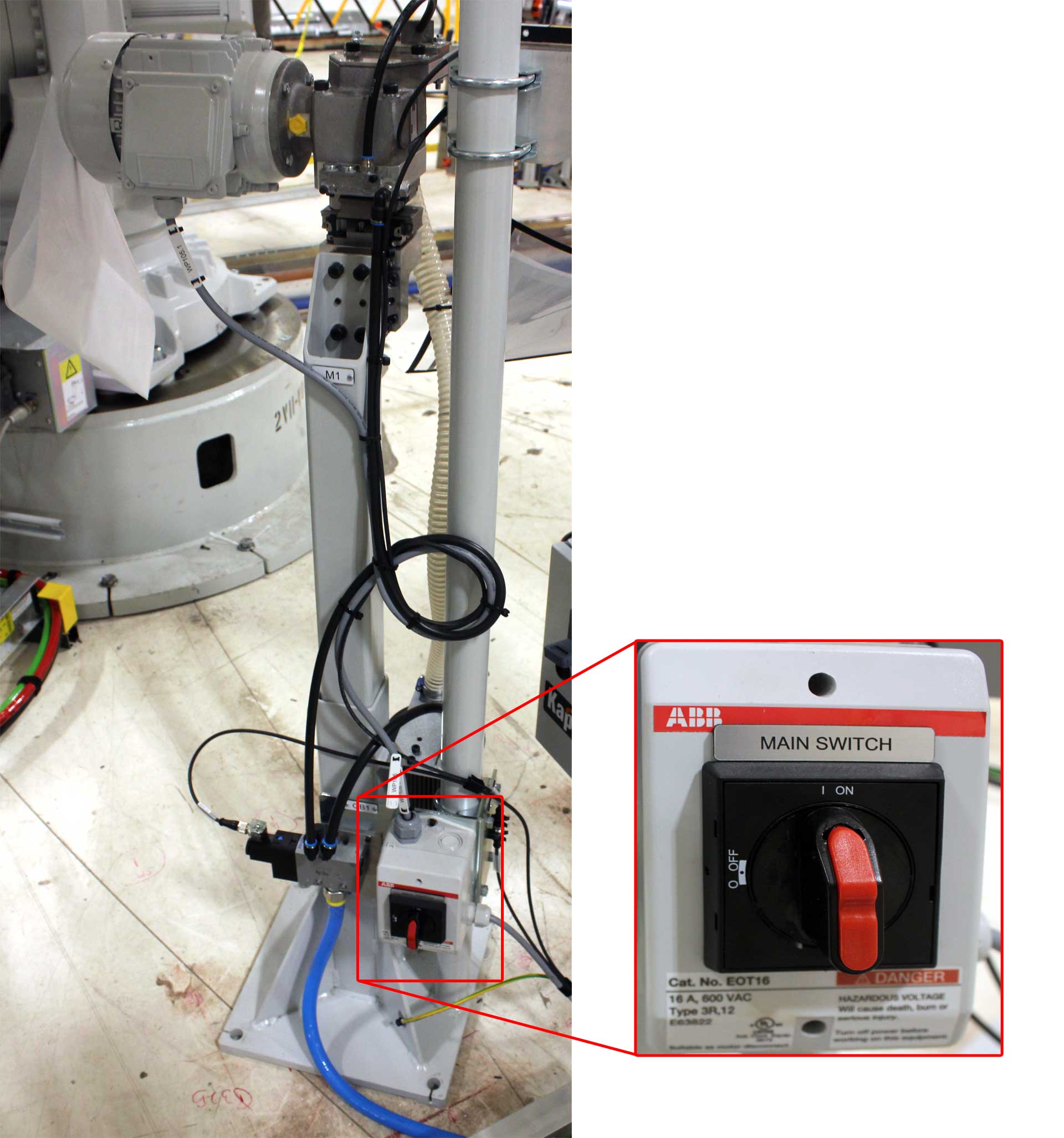

Step 2: Brauer Systemtechnik Cap Changers

- At each Brauer Systemtechnik Cap Changer, rotate the disconnect switch to the "ON" position.

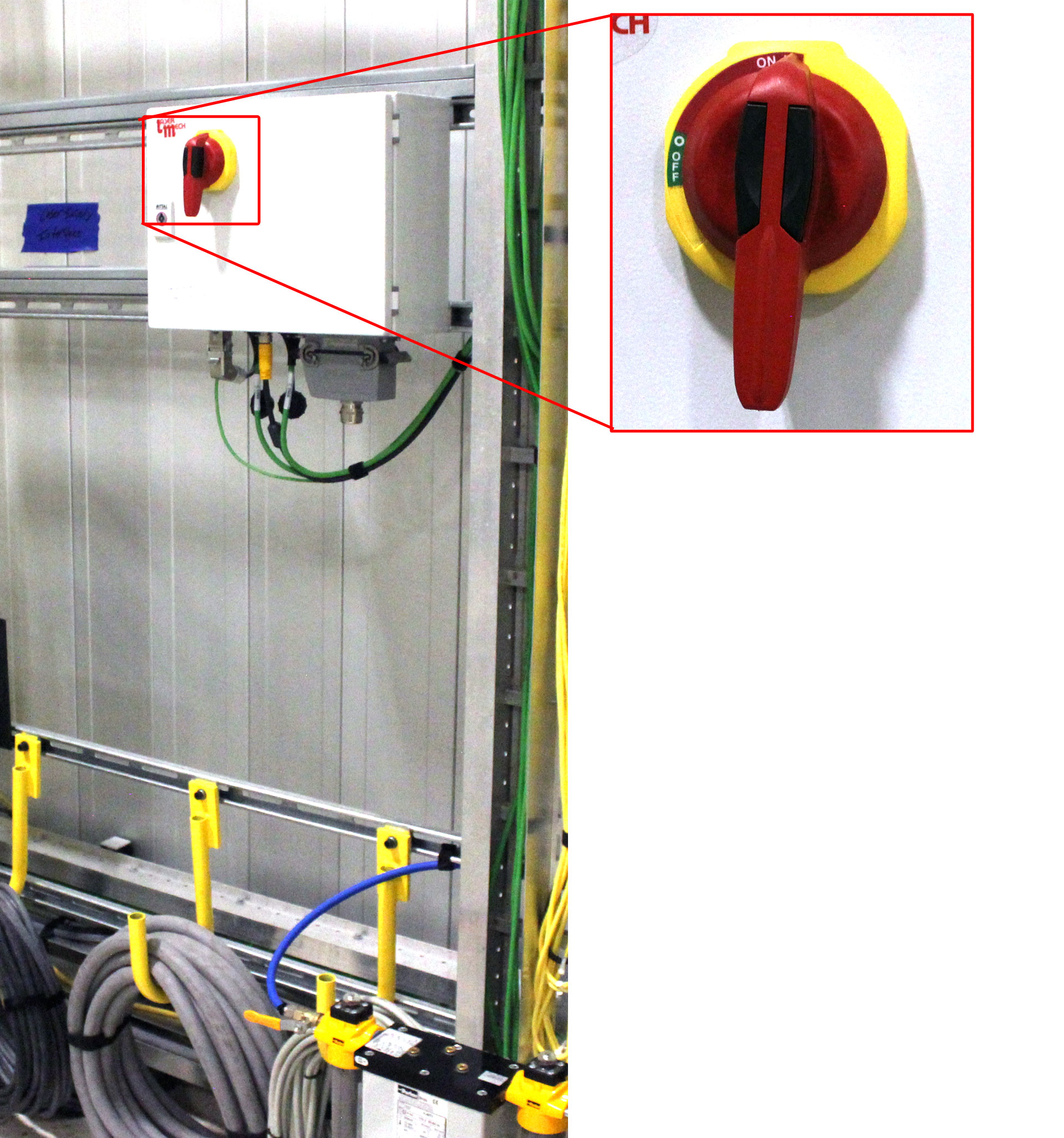

Step 3: Pedestal Sealer Stand

- At each Pedestal Sealer Stand, place Oil Switch in the "ON" position.

Step 4: Safety Lockout Pins

- Verify all Safety Lockout Pins have been removed and any maintenance completed before powering up the equipment.

Step 5: Safety Gates

- Before closing the safety gate, ensure there are no personnel within the cell performing maintenance, repairs or troubleshooting the equipment. Ensure all tools, carts, rags, etc. are removed from the work area.

- After all personnel have exited the work area, close and latch the safety gate.

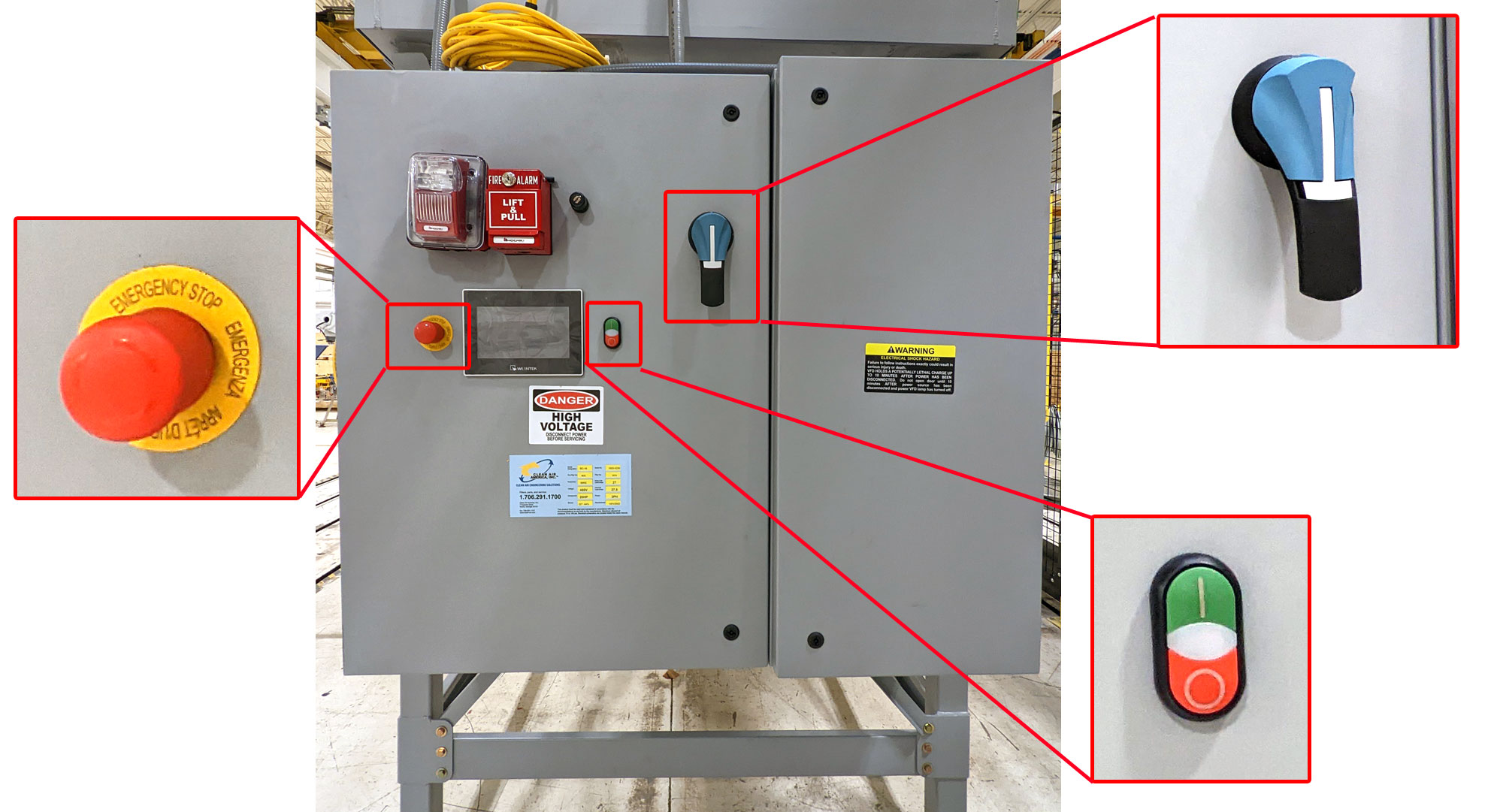

Step 6: Power Distribution Panel (PDP) Uninterrupted Circuits

- If control power had been shut off, open the Power Distribution Panel (PDP) and rotate the uninterrupted power rotary switch to the "ON" position at each PDP.

- Close and latch the PDP door.

Step 7: Power Distribution Panel (PDP) Disconnect

- Power on the Power Distribution Panel (PDP) by placing the Main Electrical Disconnect switch to the "ON" position.

Step 8: Weiss Variable Frequency Drive Controller

- Power on all four (4) Weiss Variable Frequency Drive Controllers (VFD) by placing the electrical disconnect switch to the "ON" position.

Step 9: ABB IRC5 Robot Controller Single Cabinet

- At each ABB IRC5 Robot Controller, Rotate the Main Power Selector Switch to the "ON" position.

Step 10: ABB Weld Controller

- At each ABB Weld Controller, rotate the disconnect switch to the "ON" position.

Step 11: Laser Mech Control Panel

- Make sure all doors are closed to the laser booth.

- At the Laser Booth, rotate the selector switch to the "ON" position on the Laser Mech Control Panel.

Step 12: Laser Booth Resonator

- At the IPG YLS-2000 Laser Controller, ensure the Emergency Stop (E-Stop) button is reset.

- Power up by placing the main power disconnect switch to the "ON" position.

- Ensure the power key switch is set to remote so the control of the laser module will be powered up/down at the system level. If not, press the start button.

- Ensure the service mode key switch is set to the Off position. The red service light should be off.

- The interlock indicator is an illuminated button. If it is on, there is something wrong with the interlock circuit. Press the button to test and make sure the bulb is in good working condition.

- If the laser requires service in a high humidity environment, it is necessary to leave the cooling water off during this period. Upon completion of service, and doors/panels been closed/installed, follow the instructions listed in bullet point 2.

Step 13: Laser Booth Resonators Power Up Considerations

During the power up of the laser booth, the following considerations regarding humidity should be taken into account.

- All doors and panels on the laser should remain closed and installed even when the laser is not being operated.

- If the laser has been exposed to a high humidity environment, it is recommended to turn power on to the laser without supply cooling water and check the software for the current dew point measurement. If the dew point is reporting high, let the built in dryer bring the dew point down to an acceptable level.

- When the laser is not in operation, it is recommended to turn off the cooling water.

- Ensure the service mode key switch is set to the Off position. The red service light should be off.

- The interlock indicator is an illuminated pushbutton. If it is on, there is something wrong with the interlock circuit. Press the button to test and make sure the bulb is in good working condition.

Step 14: Laser Booth Chiller

- Rotate the Laser Booth Chiller disconnect switch in the "ON" position.

Step 15: Laser Booth Chiller Water

- Place the Main Supply Return Ball Valve in the "OPEN" position.

- Place the Main Supply Ball Valve in the "OPEN" position.

- Place the Optical Supply Ball Valve in the "OPEN" position.

- Place the Optical Return Ball Valve in the "OPEN" position.

- Place the Optical Drain Ball Valve in the "CLOSED" position.

- Place the Main Drain Ball Valve in the "CLOSED" position.

Step 16: Laser Booth Variable Frequency Drive (VFD) Panel

- At the Laser Booth VFD Panel located near the laser booth door, ensure the Laser Booth VFD Panel Emergency Stop is reset.

Step 17: Laser Booth Adsorption Dryer

- Place the On/Off switch in the "ON" (1) position.

Step 18: Date Scribe Controller

- Place the On/Off switch in the "ON" (1) position.

Step 19: Dust Collector

- Place the disconnect in the "ON" position.

- Place the "ON/OFF" button in the "ON" position.

- Ensure that the "Emergency Stop" (E-Stop) button is reset.

Step 20: Atlas Copco Sealer Controller

- Place the Main Switch rotary disconnect in the "ON" position.

Step 21: ABB Transformer Neutral Panel

- Place the Main Switch rotary disconnect in the "ON" position.

Step 22: ABB Integrated Dispensing Connector (IDC)

- Place both the Main rotary disconnect and Heat rotary disconnect in the "ON" position.

Step 23: ABB Dual Drum Media Supply Systems and Controllers

- At each ABB Media Supply System and Controller, ensure that controller is placed into the "EXTERNAL" position (turn to the right) on the Key Switch.

- Ensure that the "Emergency Stop" (E-Stop) buttons are reset.

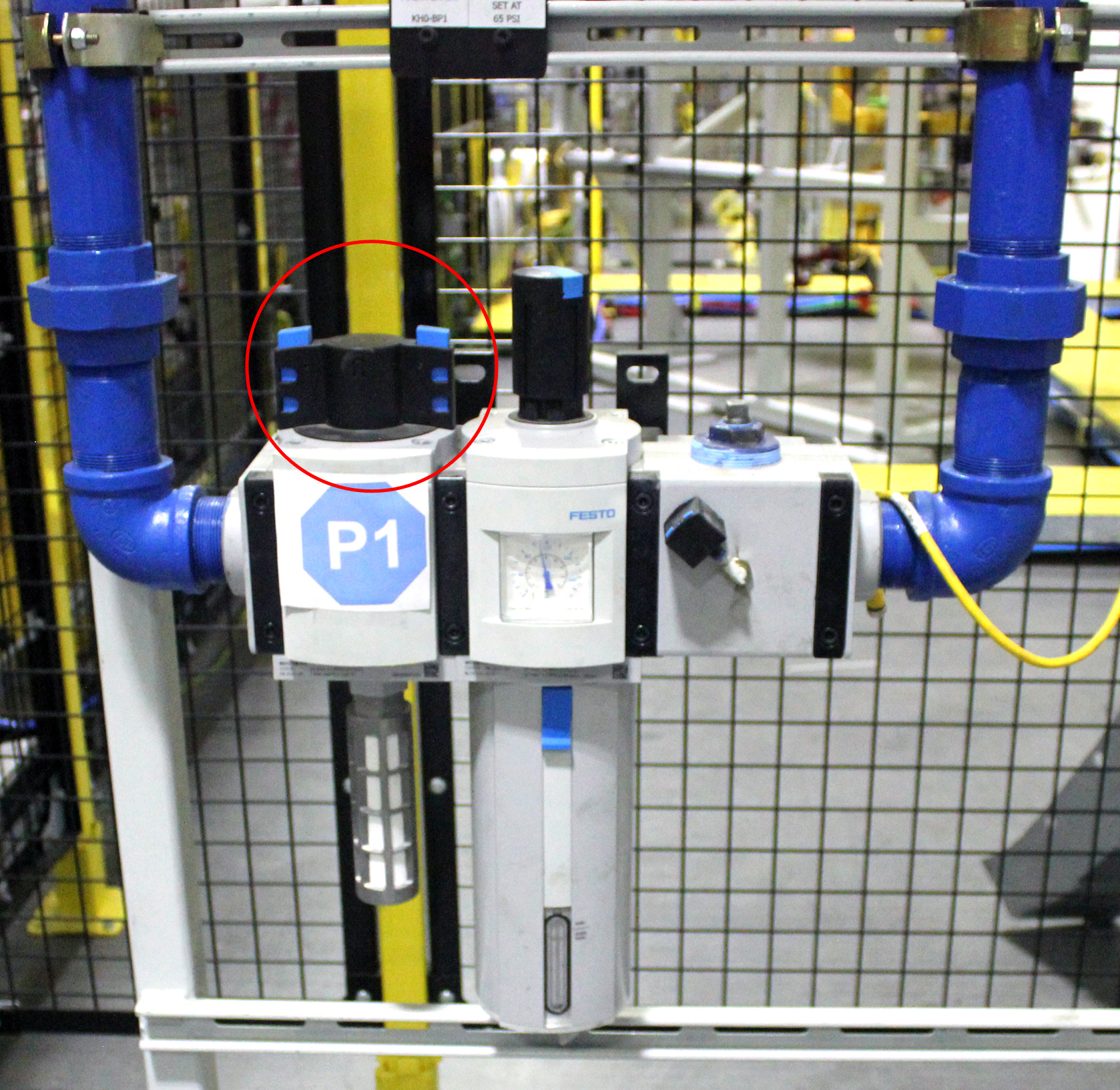

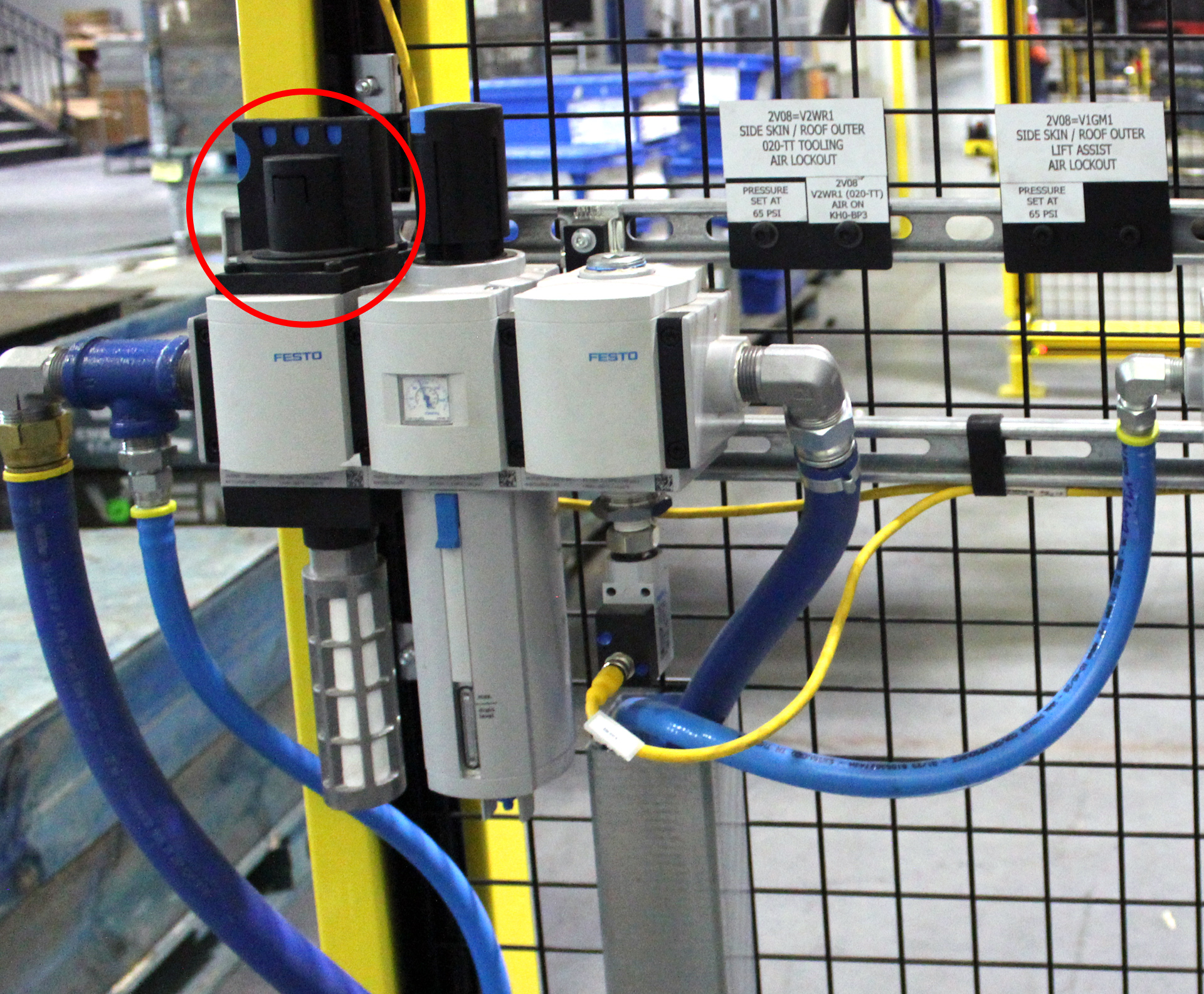

Step 24: Main Air Distribution Panel

- At the Main Air Distribution Panel, rotate the safety lockout valve to the "OPEN" position.

- On the pressure regulator unit, verify the incoming air is set to the safe, required operating pressure.

Step 25: Ancillary Air

- At the Station Level Air Distribution Panels (or Ancillary Air Panels) Place the Safety Lockout

Valve to the "OPEN" position.

- On the pressure regulator or digital pressure switch, verify the incoming air is set to the safe, required operating pressure

- Ancillary air panels are located at many locations, including turntables, robots, laser booth, and the ABB Drum Media Supply Systems.

- At the Laser Cutting Booth Adsorption Dryer, make sure the ball valve is placed in the "OPEN" position.

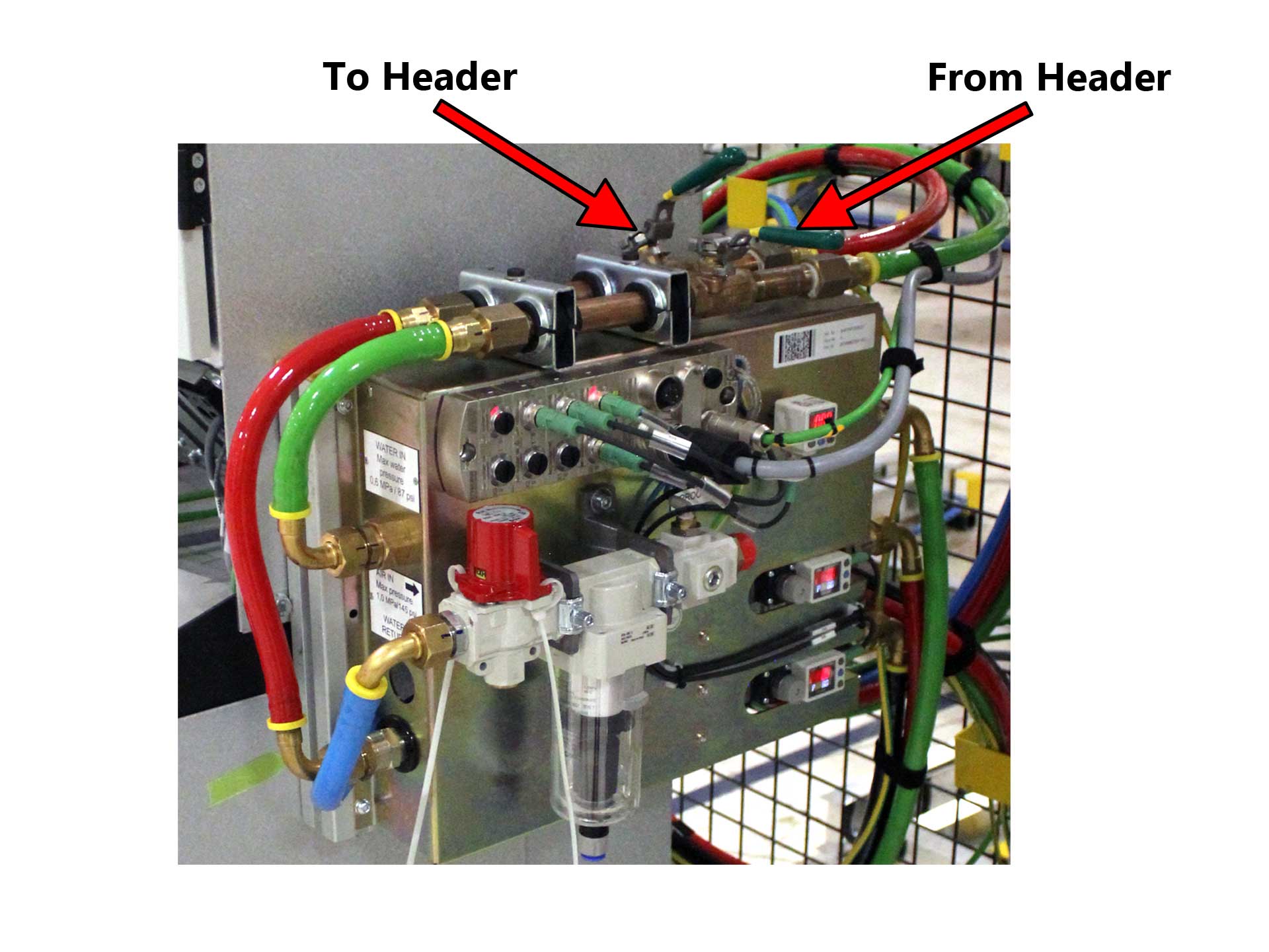

Step 26: Water System

- Place the Plant Water In Ball Valve to the "OPEN" position.

- Place the To Header Ball Valve to the "OPEN" position.

- Place the From Header Ball Valve to the "OPEN" position.

- Place the Plant Water Out Ball Valve to the "OPEN" position.

- On each ABB Weld Controller, place the To Header and From Header Ball Valves to the "OPEN" position.

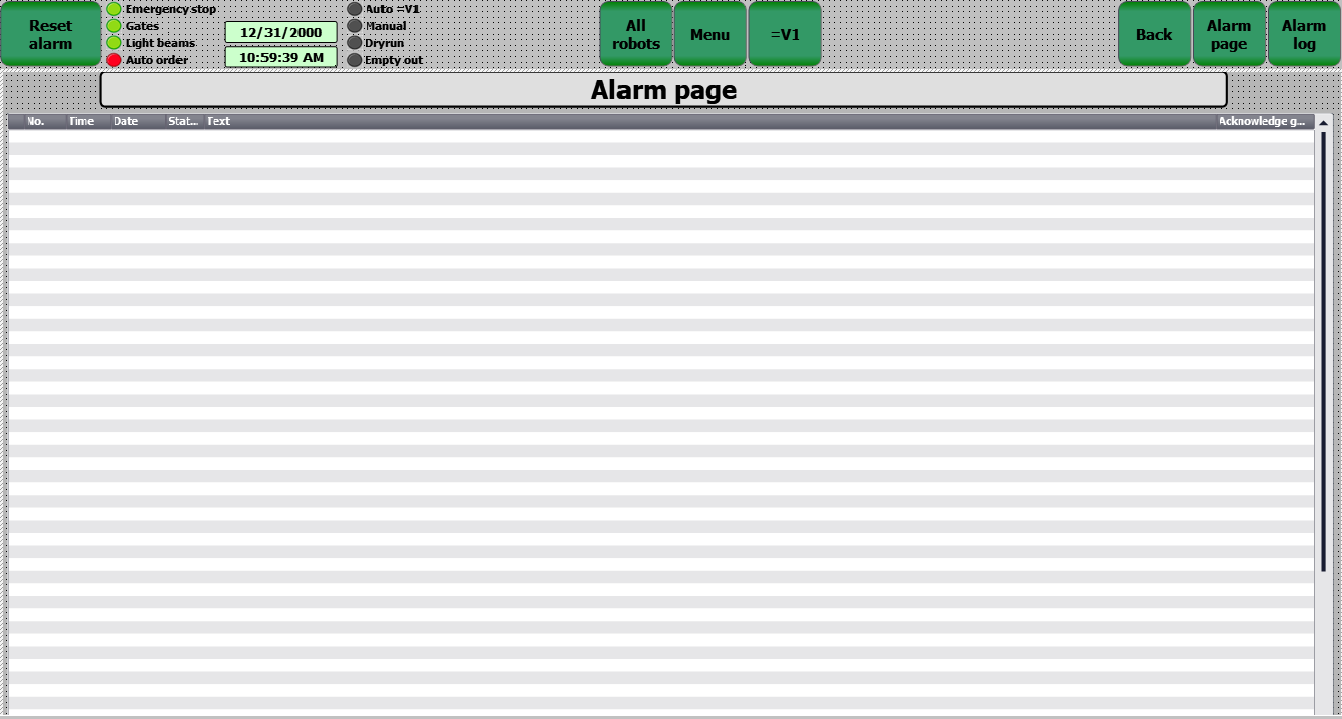

Step 27: Main Operator Panel (MOP) - Alarm Screen

- At the Main Operator Panel (MOP), view the Alarm Screen for any faults that have occurred with the 2V08 Sideskin Roof Outer Cell.

- If any faults have occurred, locate and rectify the fault.

- Press the "Reset Alarm" button in the top-left corner of the screen to clear the faults from the Alarm Screen. If the Alarm Screen indicates there are still faults within the cell, continue rectifying the faults until all faults have been corrected.

Step 28: Main Operator Panel (MOP) - Start Auto Button

- After all faults have been corrected, place the two-position selector switch into the "AUTO" position.

- Press and hold the "Start auto" button for four (4) seconds. The alarm horn will sound alerting personnel that the 2V08 Sideskin Roof Outer Cell is entering Automatic Mode of Operation.