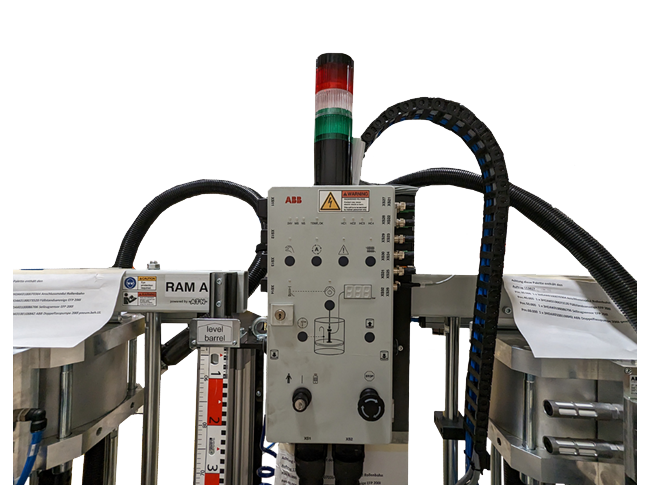

ABB Sealant Supply System

General

The ABB Sealant Supply System supplies the Sealer Robots at Stations 040 with the required sealant material. The dual drum system incorporates a controller that will receive a signal from the robot controller, informing it of which program to execute. The dual drum controller will then execute the necessary functions to dispense the material at the stand.

On the top of the Dual Drum System, there is a stack light that allows for personnel to quickly identify the status of either drum or the controller. On the front of the dual drum controller, there is a key switch that allows for personnel to perform a barrel change or stop the sealer system.

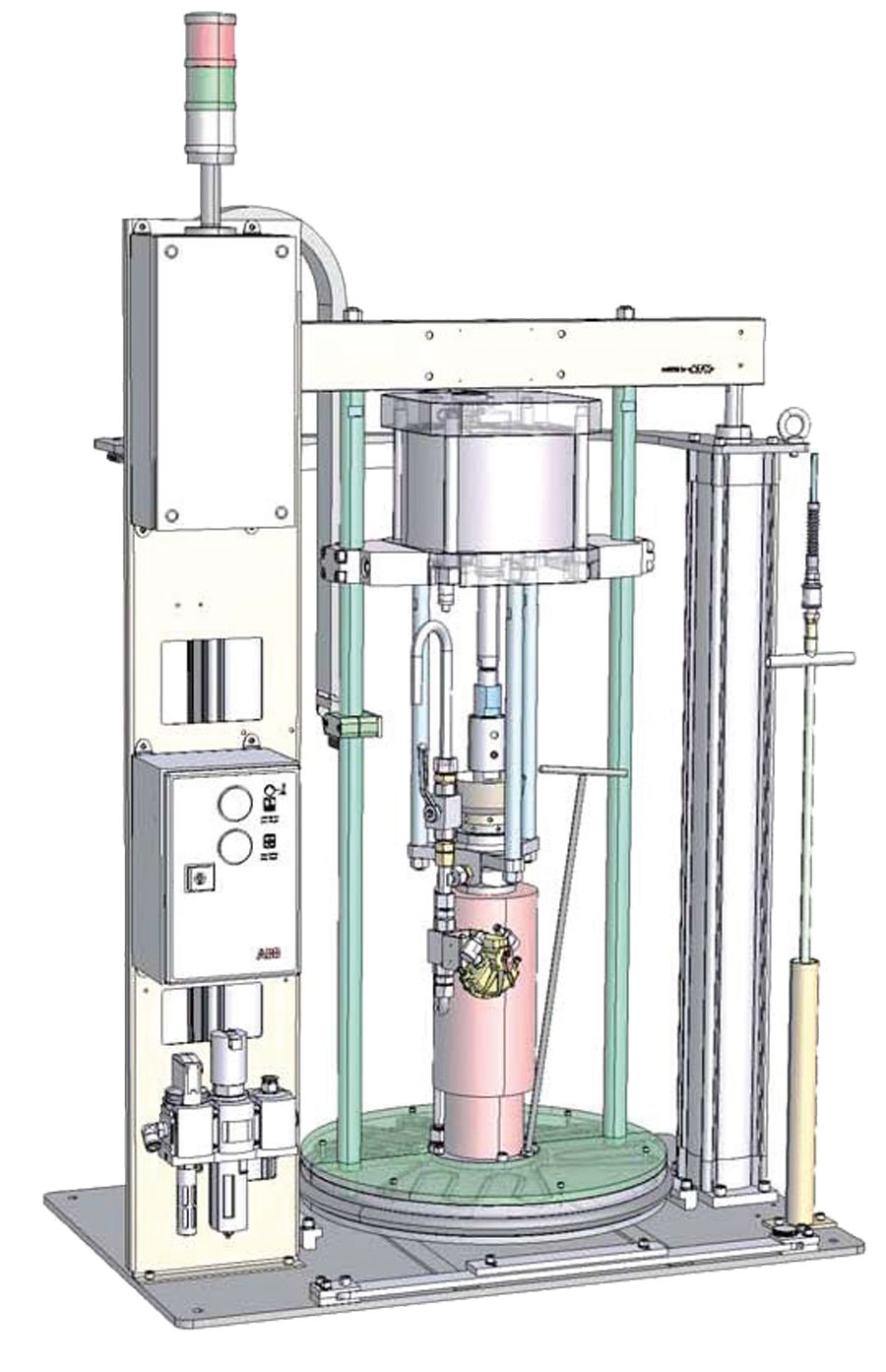

Major Components

The ABB Sealant Supply System features the following components.

| Item | Description | Function |

|---|---|---|

| A | PIM | Interface between pump and IDC. The pump with the optional heater can be operated from the IDC. Actuators are also actuated and data read from sensors. |

| B | Ram Press | A pneumatic cylinder connected to a crossbar generates pressure on the contents of the barrel with the follower plate. |

| C | Air Motor | The air motor drives the material pump. |

| D | Bleed Valve | The bleed valve vents the material pump after a barrel change. This prevents air from entering the material pipe system. In an emergency or when shut down for maintenance the installation must also be depressurized on the material side with this valve. |

| E | Air Motor Coupling | The coupling connects the air motor to the material pump. It compensates for varying axial tolerances between the two (2) assemblies. This extends the service life of both assemblies. The coupling makes it easy to disconnect the air motor and lower pump for maintenance. |

| F | Ventilation Valve | The ventilation valve is integrated in the ventilation rod. It ventilates the barrel when the follower plate is withdrawn from the barrel. |

| G | Sealing Plug | Closes the ventilation opening of the follower plate. |

| H | Ventilation Rod | It is screwed into the ventilation opening of the follower plate when a barrel is changed. It ventilates the interior of the barrel when the follower plate is withdrawn from the barrel. |

| I | Pneumatic Box | The pressures for the air motor and the pneumatic cylinder are set at the lockable pneumatic box. |

| J | Material Pump | Transports the material from the material barrel to the location of use. The material is placed under pressure when it is requested. |

| K | Compressed Air Supply Unit | Reduces the building-supplied compressed air pressure to 6 bar. The pump can be depressurized with the main valve, and shutting down the function package shuts down the pump. |

| L | Follower Plate | Presses the material out of the barrel to the lower pump. |