Tucker Feed Units

General

The Tucker feed units are comprised of two pieces: the Bowl Feeder (TF12) and a Step Feeder (TF21). Each feed unit feeds studs to the operation and welds the studs to the part once the part is in position. The Tucker controller programs the speed at and timing of the stud feeding and the Tucker power unit controls power to each of the Tucker controllers and feed units in this operation.

The slide moves into the rear setting so that the next weld stud can slide off the feed rails into the stud slide. The stud slide than moves to its front setting (Home position). The feed cycle is repeated by a new starting signal. These feed cycles are repeated until the weld studs on the feed rails are processed. If the studs are used up in the storage container, the LED on the keypad will slowly flash and the status lamp blinks.

There are two (2) Tucker Feed Units located in the 2V10 Bodyside RH Cell.

| Item | Description | Function |

|---|---|---|

| A | Bowl Feeder (TF12) | A vibratory instrument that supplies studs to the robot automation for welding purposes. |

| B | Step Feeder (TF21) | Step feeders work by raising steps which create an upwards waterfall effect. The component parts are transported into the rail of the singling mechanism through various steps. Vibration is only used in the vicinity of the rail to position the parts correctly for automatic feeding. |

Major Components (Bowel Feeder)

The Bowl Feeder features the following components.

| Item | Description | Function |

|---|---|---|

| A | Control Panel | The controls consist of the electrical controls, the pneumatic control components, the control panel and the front plate with connection ports. The pneumatic components control the feeding speed and the slider speeds. |

| B | Replenishment Shaft | Supplies new studs into the system. Studs are loaded into the shaft from the top and at the bottom of the shaft there is an opening or gate that allows a controlled release of studs into the feed mechanism. |

| C | Crane-Eye | Used in transportation of the stud weld feeder system. |

| D | Separation Block | The separator receives the studs / Tucker nuts from the vibrating conveyor bowl and feeds them into the separating block in the correct position. The separating block pushes the studs / Tucker nuts individually into the the feed hose connection. A compressed air pulse moves the studs or Tucker nuts up to the next unit in the feed system through the feed hose. |

| E | Lifting System | Lifts the stud fasteners from the base metal upon triggering. |

| F | Vibratory Conveyor | A vibratory drive in the vibrating conveyor bowl transports the welding studs / Tucker nuts upwards via a spiral and then feeds them into the correct position in the separator. |

| G | Level Sensor | The level sensor measures the filling level in the vibrating rail. If the filling level falls below the setting, it will switch on the vibrating rail’s vibrating drive so that the studs are fed in. |

| H | Base Plate | Used to support and position the weld stud feed system. |

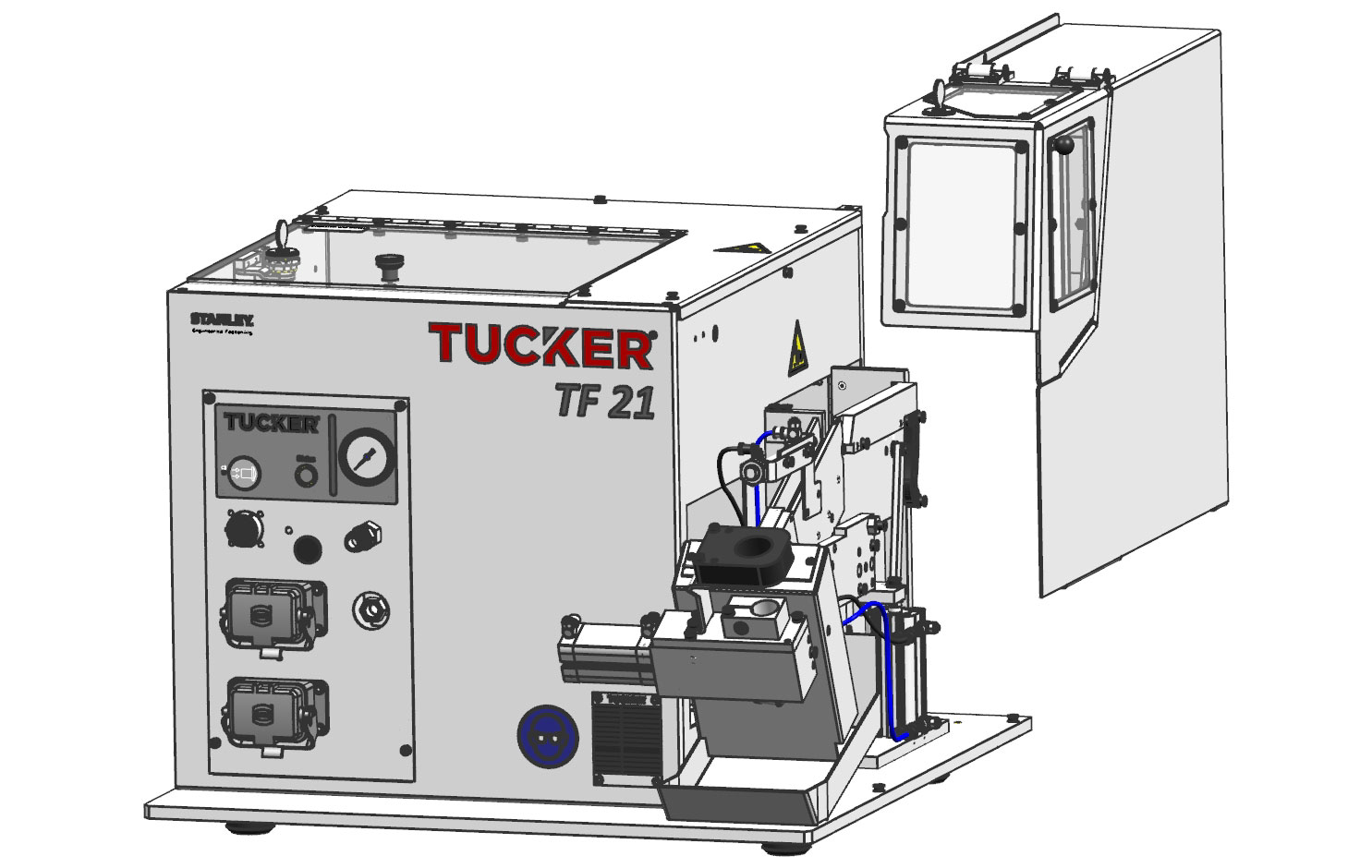

Major Components (Step Feeder)

The Step Feeder features the following components.

| Item | Description | Function |

|---|---|---|

| A | Filling Shaft | Used to refill system with weld studs. |

| B | Control Panel | Manometer display, status display and membrane key. |

| C | Stud Exit Sensor | Tests whether a weld stud has left the feeder during the feed. |

| D | Separating Block | Separates the weld studs. |

| E | Lifting System | Moves those studs out of the bin. |