Brauer Systemtechnik KAPPOSTAR Cap Changer

General

The 2V11 Bodyside Sub Cell features Brauer Systemtechnik KAPPOSTAR Cap Changing Units. After a programmed number of welding and tip dressing sequences, the robot will move over to the Cap Changer to remove the old welding caps and be replaced with a new pair. To remove the welding caps, the robot will lower the weld gun into one of the two Cap Changer Pucks. Once in position, the pucks will rotate, removing the caps from the weld guns.

After the caps are removed, the robot will move over to the magazine assembly to have a new cap installed. To verify the caps are secured to the weld gun, robot will move over to the verification piece and press on the caps. Once verification process is completed, the weld gun will move to the tip dresser to ensure the proper diameter and dimensions are correct before resuming the welding operations.

There are four (4) different models of KAPPOSTAR Cap Changers that are used on these machines, which function the exact same. Each is for different orientations or are single or double tip changers that are required for proper operation. These four (4) models are:

- BWS 5700 Type H

- BWS 5700 Type V2

- BWS 5710 Type H

- BWS 5710 Type V2

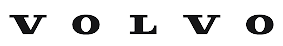

Major Components (BWS 5700 Type H)

The BWS 5700 Type H model is a single tip changer with a horizontally arranged gear unit and cap extraction unit.

| Item | Description |

|---|---|

| A | Electrode cap cartridge |

| B | Sensor B2/B3 - Fill level monitoring of the electrode cap cartridge |

| C | Pressing plate - Presses the electrode cap cartridge |

| D | Gear unit |

| E | Sensor B1 - Checks the revolution of the gear motor |

| F | Electrode cap changing system |

| G | Sensor B4 - Queries electrode cap extracted/pressed on condition |

| H | Gearbox motor |

| I | Electrode switch box |

| J | Electrode cap collecting box |

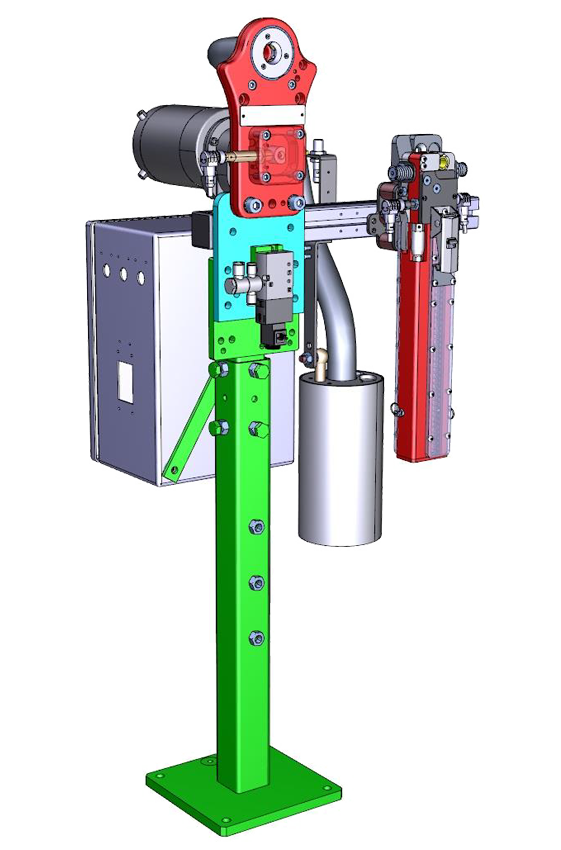

Major Components (BWS 5700 Type V2)

The BWS 5700 Type V2 model is a single tip changer with a vertically arranged gear unit and cap extraction unit.

| Item | Description |

|---|---|

| A | Electrode cap changing system |

| B | Gear unit |

| C | Gearbox motor |

| D | Electrode cap extraction unit |

| E | Electrical switch box |

| F | Solenoid valves - Electrode cap extraction unit |

| G | Pressing plate - Pressing the electrode cap on |

| H | Sensor B1 - Checking the revolution of the gearbox motor |

| I | Sensors B2/B3 - Fill level monitoring of the electrode cap cartridge |

| J | Electrode cap cartridge |

| K | Collector bag |

Major Components (BWS 5710 Type H)

The BWS 5710 Type H model is a double tip changer with a horizontally arranged gear unit and cap extraction unit.

| Item | Description |

|---|---|

| A | Electrode cap cartridge |

| B | Sensor B2/B3 - Fill level monitoring of the electrode cap cartridge |

| C | Pressing plate - Presses the electrode cap cartridge |

| D | Gear unit |

| E | Sensor B1 - Checks the revolution of the gear motor |

| F | Electrode cap changing system |

| G | Sensor B4 - Queries electrode cap extracted/pressed on condition |

| H | Gearbox motor |

| I | Electrode switch box |

| J | Electrode cap collecting box |

Major Components (BWS 5710 Type V2)

The BWS 5710 Type V2 model is a double tip changer with a vertically arranged gear unit and cap extraction unit.

| Item | Description |

|---|---|

| A | Electrode cap changing system |

| B | Gear unit |

| C | Gearbox motor |

| D | Electrode cap extraction unit |

| E | Electrical switch box |

| F | Solenoid valves - Electrode cap extraction unit |

| G | Pressing plate - Pressing the electrode cap on |

| H | Sensor B1 - Checking the revolution of the gearbox motor |

| I | Sensors B2/B3 - Fill level monitoring of the electrode cap cartridge |

| J | Electrode cap cartridge |

| K | Collector bag |