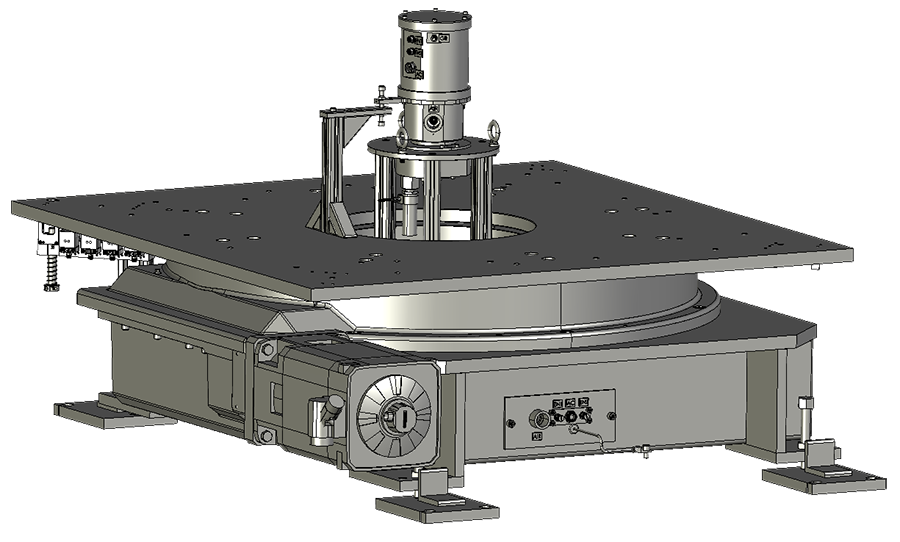

Turntable

General

The turntable located in the 2V11 Bodyside Sub Cell is made by Weiss (CR1300) and have four (4) Geo Fixtures mounted on top (not shown). The four (4) Geo Fixtures allow for the operator to load parts on one fixture while the robot is currently performing the welding operations on the opposite side of the turntable's fixture. When the operator load and weld processes are completed, the turntable rotates and the process is completed. To rotate the Geo Fixtures, the turntable features a Siemens SIMOTICS 1FT7108-5AC71-1CH servo motor that allows for the turntable to rotate to the correct position.

Major Components (CR1300)

The Turntable features the following components.

| Item | Description | Function |

|---|---|---|

| A | Service Union | The service union allows for all incoming air to be distributed to required equipment such as manifolds, clamps, etc. |

| B | Position Sensors | Detects the position of the turntable. There are 5 positions: All Stop, P1 Position, P2 Position, P3 Position, and P4 Position. These sensors are attached to a Murrelectronik fieldbus I/O panel to send signals back to the system CPU. |

| C | Metal Bellows Coupling | Flexible coupling connecting the motor shaft to the turntable shaft. |

| D | Servo Motor | Siemens SIMOTICS 1FT7108-5AC71-1CH1 synchronous motor that allows Allows for turntable to rotate to the required working position. |

| E | Vent Screw | Used to relieve build-up pressure or allow air to escape from the interior of the rotary table during operation. |

| F | Cover of Shaft | Used for hand cranking the shaft, if necessary. |

| G | Sight Glass | Used to check the oil level for the turntable. |